All our components and automation systems are consistently engineered to maximize savings on materials, energy and costs,without compromising on product quality. We are your expert partner for any type of pipe extrusion line.

Suko has everything you need for producing plastic PTFE lined pipes from 5 mm to 2500 mm in diameter – including automation components for maximizing material savings.

Our product portfolio covers single-screw extruders,counter-rotating and corotating twin-screw extruders with the corresponding pipe heads, and downstream components through to fully automated PTFE corrugated tubing lines. All our components and automation systems are consistently engineered to maximize savings on materials, energy and costs,without compromising on product quality. We are your expert partner for any type of pipe extrusion line.

Benefits:– First-class system and process solutions from a single source– System solutions for efficient and effective production– Expert partner for customer-specific special solutions

Application-specific, proven line componentsOur extruders, molds, calibration systems and downstream components are tailored to your individual requirements and have already been tested multiple times. All downstream components such as vacuum tanks, spray tanks, haul-offs, cutting units, socket forming machines and additional equipment are engineered for optimum interoperability; the automation components are designed for maximum operational safety and ease of operation and servicing. All functions for control and monitoring are fully integrated into the modular extrusion line control system. The result: With Sukoptfe systems, you achieve the highest output with the greatest possible flexibility and maximum material savings. We also supply a range of optional addons for our complete extrusion systems:

Fully automated additional equipment– Seal ring insertion robots– Pipe hoist and pipe rotating units– Bundlers– Palletizers

Winding systems- We supply single and twin winders for polyolefin pipe up to 160 mm in diameter.

Additional equipment– Mixers– Material feeding systems,plus weighing and metering systems– Screen changers– Melt pumps– Wall thickness and diameter gages– Marking devices– Winches as start-up aid– Pipe bending machines– Thread-cutting machines– Shredding and grinding systems

Applications:

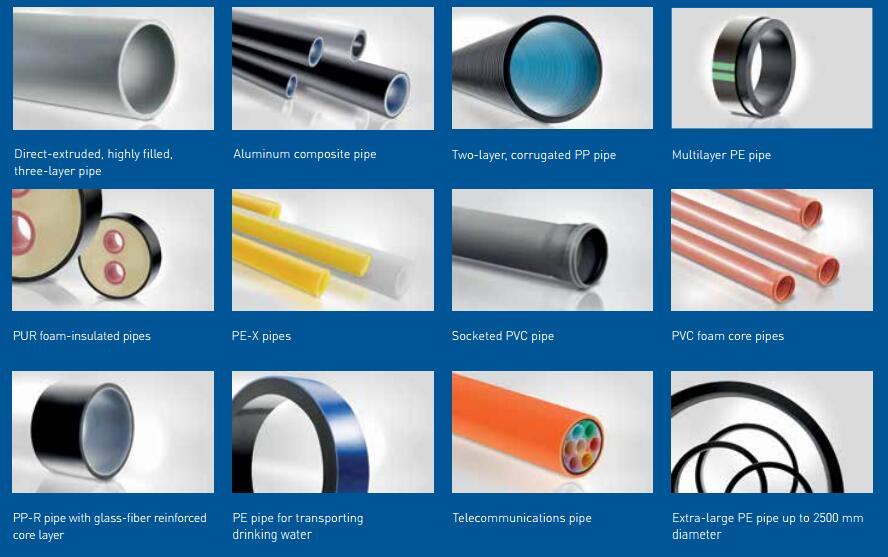

– Drinking water pipes – Sewage pipes – Irrigation pipes – Drainage pipes – Hot water and heating pipes – Cable conduits – Gas pipes – Multilayer pipes – PE-X pipes – RTP pipes – Coextruded pipes with different combinations of materials, e.g. PVC foamcore pipes – Aluminum composite pipes – Highly filled pipes – PUR foam-insulated pipes – Sheathing for steel pipe – Microduct bundles (conduit for fiber-optic cable) – Extra-large pipes up to 2500 mm diameter

Post time: Nov-04-2018